Laminated glass is made by bonding two sheets of glass with a strong special interlayer, offering excellent penetration resistance and fragment retention. Even if the glass breaks, the interlayer holds the fragments, preventing intrusion into the interior.

Key Features

- Safe - fragments do not scatter when broken

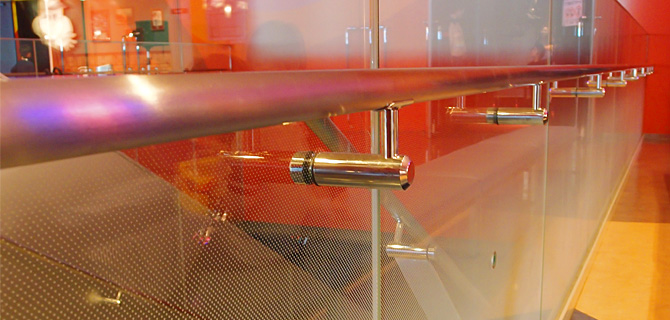

- No opening is created when broken, providing high security

- Blocks over 99% of UV rays that cause skin damage and furniture fading

- Can enhance decorative, solar shading, and security functions depending on the glass and interlayer composition

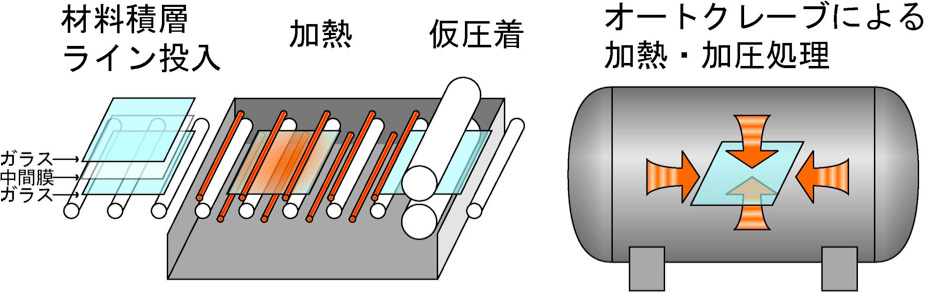

Manufacturing Method (ACV Method)

The general manufacturing method for laminated glass consists of three processes: material lamination, temporary bonding via conveyor line, and final bonding via autoclave. This is a manufacturing method suitable for mass production.

Representative products of laminated glass as specified in JISR3205. Various glass thicknesses from 3 to 19mm can be processed.

Our Products

Special laminated glass that encapsulates LEDs, LCD films, or patterned glass within laminated glass.

Our Products

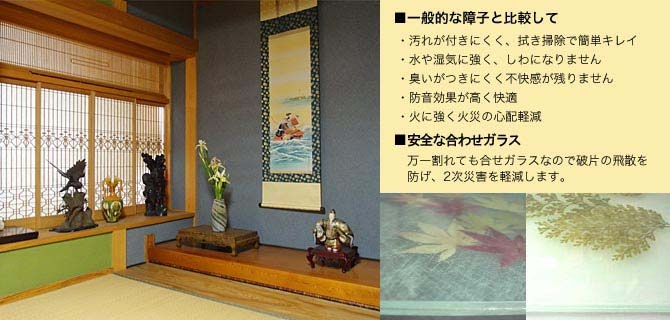

Laminated glass that combines the durability and safety of laminated glass with the decorative quality of washi paper. It creates a Japanese atmosphere without sacrificing comfort.

Our Products

A decorative glass product made from fine fragments of tempered glass. Enjoy a unique spider-web pattern different from printing.

Our Products

Laminated glass with added functions such as soundproofing and solar shading to the basic functions of laminated glass.

Our Products

A product that raises the defensive power of glass, which is considered a weak point for security and defense, to a level that can prevent gunfire. It protects the interior not only from bullets but also from hammer attacks.