Tempered glass is glass with enhanced strength compared to regular glass. While it looks the same as regular glass, its strength is improved by strong compressive stress on the surface that suppresses the occurrence and spread of scratches and cracks. There is also tensile stress inside, and by maintaining balance with the surface compressive stress, it maintains the same plate shape as before tempering.

Key Features

- 2 to 5 times the wind pressure resistance compared to regular glass

- Improved resistance to thermal breakage and impact strength

- If broken, fragments break into fine granular pieces, reducing secondary damage

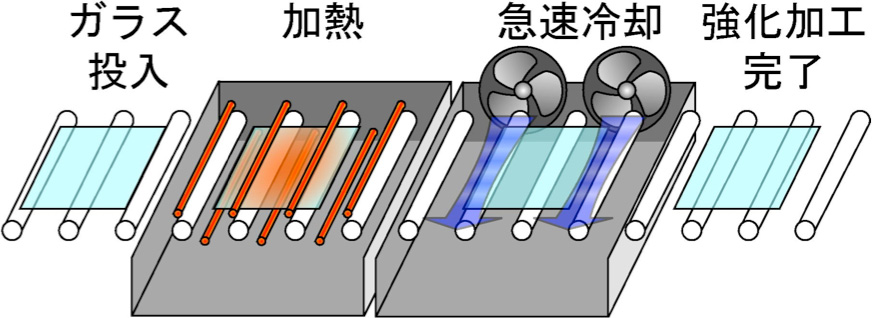

Manufacturing Method

Glass is heated in a heating furnace and cooled in a cooling furnace. The tempering stress is determined by the temperature difference between the interior and surface when the glass temperature is cooled to near the strain point (approximately 550 degrees). As cooling progresses and the temperature difference between the interior and surface disappears, stress is generated and the strength of the glass increases.

Representative products of tempered glass as specified in JISR3206. Various glass thicknesses from 4 to 19mm can be processed.

Our Products

Heat-strengthened glass as specified in JISR3222. It has twice the strength of float glass. While its strength is inferior to tempered glass, broken fragments do not become granular, making it easier to implement fall prevention measures.

Our Products

Glass that has been tempered beyond the JIS standard range. We offer both Hard (equivalent to tempered glass processing) and Soft (equivalent to heat-strengthened glass processing) types.